| HOME I PROJECKTS I CONTACT |

|---|

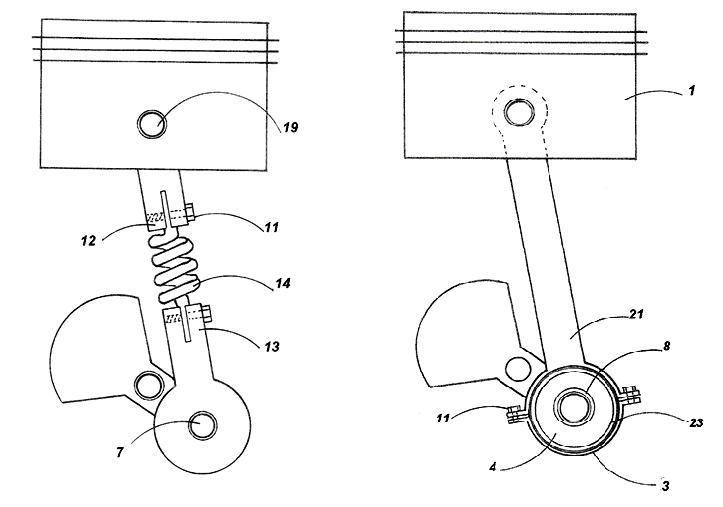

PISTON WITH DAMPER

Being adaptable to every model and design of vehicles with piston and designed to be used especially in piston compressors; the piston with damper is a product designed with the endeavor of decreasing the abrasion of eccentric shaft and bearing more and minimizing the high volume sound and vibration appeared. The system is composed of concave corrugated piston rod cap that piston rod is connected, the polymer like rubber, silicon based damper that cap preserves, the bushing acting as bearing to eccentric shaft either or roller bearing that can be used instead of bushing.

The piston with damper operates in the way of push and pull up down of the eccentric shaft of piston rod as in the existing piston compressors but differently the piston with damper transmits the shake force which appears during the motion of eccentric shaft via piston rod to damper placed between bushing and bearing, then the damper receiving the force, blocks the abrasive effect of the eccentric motion. The damper, is attached by screws to the other half, being fixed to piston rod with screws between the bushing and the clamp and dividing the clamp from the middle into two. However, differently this damper, may be squeezed in between the bearing and bushing by using a single piece bearing.

The parts in the figures are numbered one by one where the equivalents of these numbers are given below:

1- Piston,

2- Piston rod,

3- Piston rod bearing cap,

4, 5, 6- Damper,

7- Eccentric shaft,

8, 9, 10- Bushing,

11- Screw,

12, 13- Connector,

14, 15- Coil spring,

16- Seated bearing,

17- Piston seat,

18- Seated bushing,

19- Pin,

20- Upper piston rod,

21- Lower piston rod,

22- Upper piston rod bearing,

23- Outer ring.

The damper may be used in lower piston rod or in upper piston rod (20) where the piston is just connected to the rod and in the piston itself, as well. The damper (5) mounted to the seat (16) on the piston (1) is attached to the upper piston rod (20) with the bushing (8) in the middle by a pin (19) and by this means the appeared stroke and vibrations are absorbed. In the same way upper piston rod (20) absorbs the strokes by a similar installation. The damper (21) mounted to the bearing (22) on the upper piston rod (20) is attached to the piston with the bushing (10) in the middle by a pin (19) and by this means the appeared stroke and vibrations are absorbed.

The piston with damper also has a similar function with its versions with coil spring but differently here not the rubber or the silicon but the coil springs (14), (15) are used as the damper. The piston rod with coil spring is composed of the piston rod which is fixed on the bearing, the connector (12), (13) with screws which is used for fixing the coil spring on it, the seated bearing (16) which prevents the coil spring to bounce and the bushing (18) which preserves the coil spring with seats on it and which the eccentric shaft penetrates in. In a similar way, the piston rod with coil spring transmits the vibrations revealed by the eccentric shaft via piston rod to the coil springs on the rod, owing to the eccentric move softened more and more; the eccentric shaft and bushing abrasions are prohibited and the release of the high volume sound is also prevented.

The coil spring technique used in lower piston rod, with a similar adaptation may be used in upper piston rod or piston itself either but in order to repress the stroke and vibration appeared, the technique of piston with damper is used over the eccentric shaft (7) where the force came out.

The piston with damper does not have any negative effect on the performance of the compressor. Even though the motion of the eccentric shaft (7) is softened, the quantity of the air pumped in unit time is the same as in the other compressors and there is not any decrease in the quantity of the air pumped.

Abrasion rate of the eccentric shaft (7) and bushing (8, 9, 10, 18) in unit time in pistons with dampers has a smaller value when compared to the other techniques. In the existing techniques, the shake force appearing during the push and pull up down of the eccentric shaft (7) of the piston, has a strong abrasive effect over the piston rod bearing and the eccentric shaft (7). Moreover the move of piston rod forward backward with sharp turns cause a vibration and high volume sound to appear. Whereas in the piston compressor with damper, an exactly opposite situation is visible. Owing to the damper (5,6) mechanism placed on the piston (1) and the piston rod (2), the stroked abrasion force came out of shake forces of the eccentric shaft (7) is absorbed and repressing the vibration and high volume sound appeared, the abrasion of the eccentric shaft and bearing or bushing where the shaft moves in is brought to the minimum level. In addition to this, in the products that the technique is used, while the repression of the appeared sound does not expose the work environment of people to any noise, other life of vehicle is lengthened more; the periodical maintenance expenses are reduced owing to the softened eccentric shaft motion.

Di Sanat Atölyesi sanatsal etkinliklerin yanı sıra endüstriyel tasarım ve ürün geliştirmeye yönelik faaliyetleriyle de çalışmalarını sürdürmekte,bir çok patent başvurusu ve yine bu başvurulara ilişkin hazırladığı iş planları ve yenilikçi iş fikirleriyle arayışlarını devam ettirmektedir.Çok daha fazla proje için lütfen arayınız veya mesaj atınız.

| michelangelo | leonardo da vinci | kazimir maleviç | ayvazovski | van gogh | ivo andrıc | helena blavatsky |

|---|

İLETİŞİM

05375201947

bilgi@disanat.com

disanat@gmail.com

![]()

İsmet

DEMİRHAN

![]()

H.Ü

Güzel Sanatlar

Fakültesi

1998

copyright © 2014 disanat.com

,